"We create opportunities, we build strong relationships."

the thinking

Deeds, not words. Corroborate the commitment, demonstrating the dedication to work, perseverance, transparency with which we weave our relationships with the customer. The objectives must be clear, questions and concerns recognized and solved, the solutions given specifications. With responsibility and a spirit of sharing.

"Knowledge and experience to the best possible solution."

the thinking

Do well and do it better, forever. This is the process in order to support and solve every request. And we must remember that we are a part of this process. The end is shared. The realization of complex projects from mechanics, requires the need for a working group, coordinated in time and content, faced with rationality, but also reflection and enthusiasm.

"We give life to your projects, we switch on solutions."

the thinking

My job is to give life to things, make them moving. Technology is our ally, but it is the human knowledge to guide it to success. Analysis and information for the best choice. Understand, evaluate, act: this is our method.

"We respect time & methods. We consolidate answer"

the thinking

Professionalism, competence and precision in every detail. Nothing must be left to chance or improvisation. The quality in every aspect of our work, the beacon that guides us. Discipline our mantra. Doing well, immediately and then every time a little better. Our experience, applied with rigor and method, to be sure to have built wonderful machines.

At Riello Sistemi the future comes first, since more than 50 years

We started in 1963 and we never stopped. Today it remains our firm intention to continue to promote the development of the technology for the future. We are proud to be leaders in the global market.

1963

On 1 January 1963 born in Minerbe Riello Sistemi, a small town near Verona

The production plant is initially only 1,000 sq/m of offices and the workshop is 4.000 sq/m

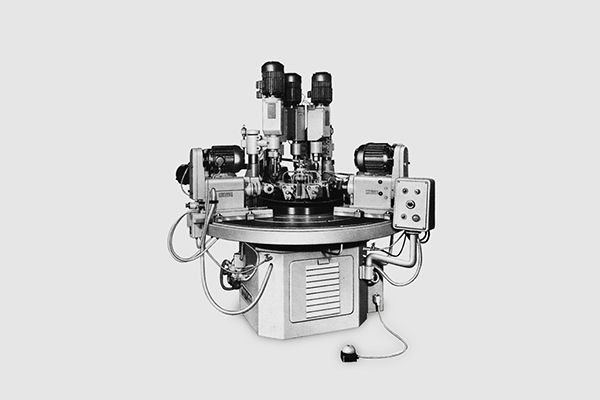

1965

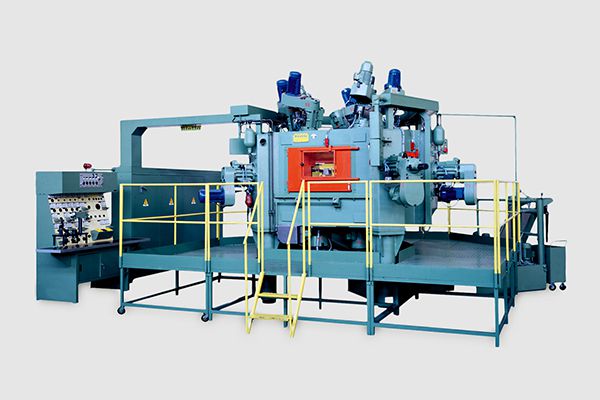

The first Rotary Transfer Machines are sold and exported to the main markets of the world

1970

Riello develops a new model of Rotary Transfer machine: The Trunnion Type

Riello Sistemi, in Minerbe, built up a new assembly area of 2,500 sq/m

1975

Riello Sistemi invent the Rotary Transfer machines with mechanical preset

Riello Sistemi open a direct sale office in Chicago (USA) to be closest with North American market

1980

The new revolutionary Rotary Transfer Machines Arrivano with the table suspended arrived on market:: THE VERTIMAC

1985

Transfer machines become fully CNC. Hydraulic first, and then Mechanic

1990

A new fantastic product arrive: the Flexible Transfer Machine VERTIFLEX

The range of Flexible Transfer VERTIFLEX is completed by the "Vertiflex 300" and the "Vertiflex 450"

Riello Sistemi doubles the surface of the offices in the establishment of Minerbe coming to 2.000 sq/m

1995

Riello Sistemi Acquires the Company COMAS in Montecchio Vicentino (Vicenza)

The continuous success requires the extension of the assembly area with the construction of a further area of 2.000 sq/m

Riello Sistemi does not stop in fornt at anything. To meet the demands of a North American customer sends two Rotary Transfer lines from Verona hiring two monsters planes ANTONOV

2000

Riello Sistemi acquires Mandelli Sistemi S.p.A.

Riello Sistemi opens in Shanghai Riello Sistemi China with 15 employees for the sale and servicing the Asian market

With the acquisition of Mandelli Sistemi and the opening of direct subsidiary in China, Riello Sistemi joined the Gruppo Riello Sistemi

2005

A new product is added to traditional Rotary Transfer: the line Twin and Four spindles MC machines

The range of Flexible Transfer Machines is completing adding to the Vertiflex model a new machine: a new model: the TFL

Riello Sistemi acquired in Canada, Windsor, the Tri-Way to strengthen its presence in the North American market

2010

Riello Sistemi is 50 years old. In October 2013 Riello Sistemi celebrates this milestone by hosting at its seat more than 600 guests, including customers, suppliers and collaborators.

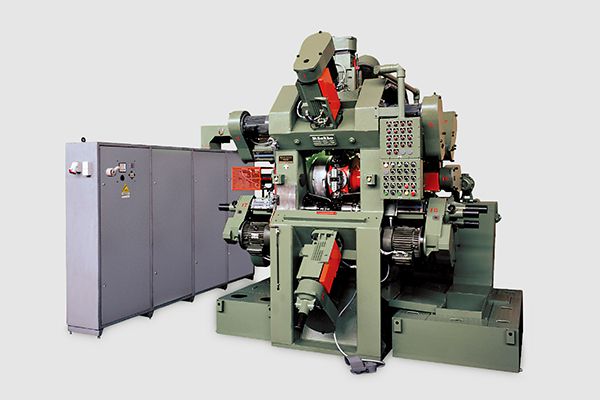

Riello Sistemi renews the main components of Traditional Transfer reconfirming technology leader in the industry.

2015

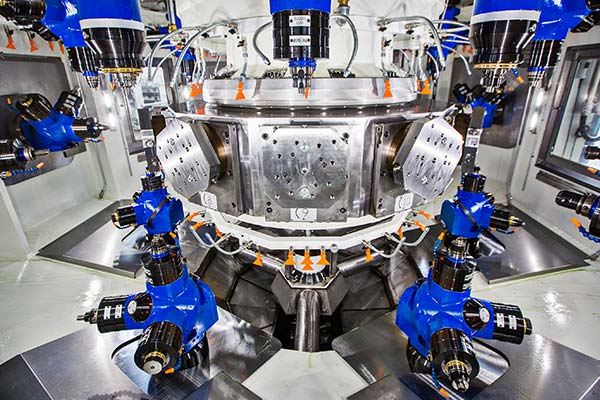

A new generation of Flexible Transfer Machines is born: the TFL 400

Together with the established Vertiflex 300 and Vertiflex 450, this new machine generation completes our product range increasing production capacity

Up to 21 Operating Units working simultaneously, with more than 100 tools available

2020